Okuma MCR-BV: Innovate Without Limits

Published May 30, 2025 | Posted in Manufacturing, News, Technology

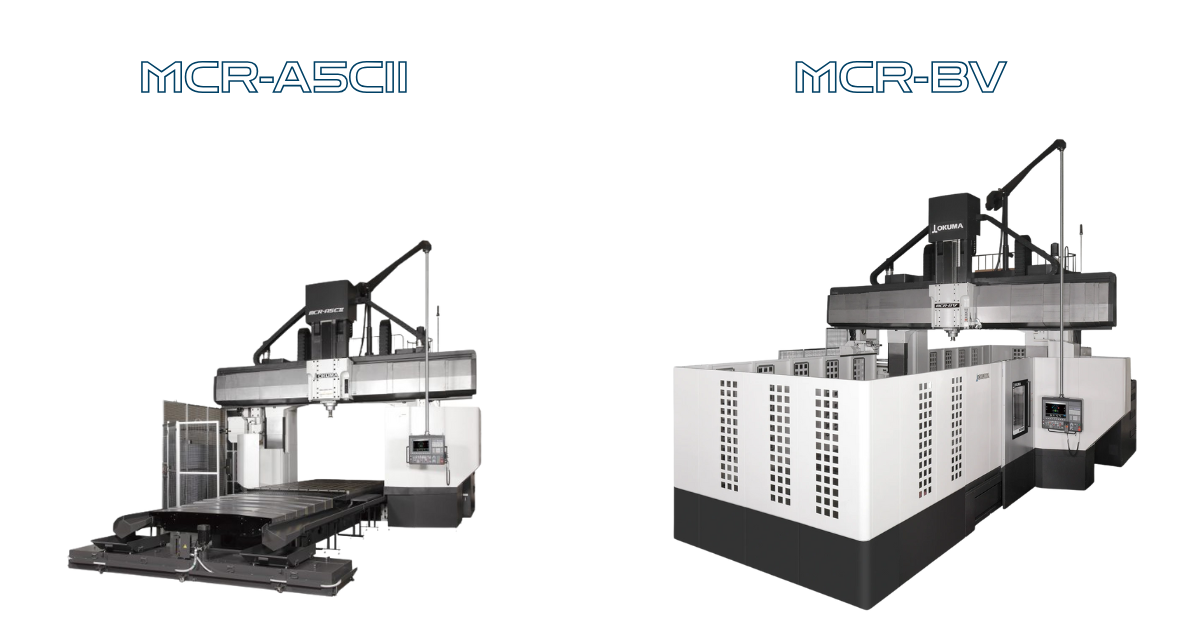

Cavalier Tool’s commitment to precision and innovation has driven our growth for fifty years—and our newest Okuma MCR‑BV installation is the latest chapter in that story. By adding this new Double Column Machining Center alongside our two trusted MCR‑A5CII machines, we’re expanding capacity, boosting versatility, and reinforcing our promise to deliver faster, more complex parts without compromise.

From Proven Performance to New Possibilities

For the past several years, our pair of Okuma MCR‑A5CII Double Column Machining Centers have enhanced our efficiency in complex operations on medium sized parts. They’ve handled five‑face machining, heavy‑duty roughing, drilling, 2D, and compound angles with a level of reliability that has earned them a permanent spot in our machining processes. The new Okuma MCR‑BV joins them at Cavalier Plant 2 as a capacity‑expanding complement — ready to tackle the biggest jobs our customers can offer.

“The MCR‑A5CII’s have served us brilliantly. Adding Okuma’s MCR‑BV means we can take on larger workpieces and even more complex toolpaths, all under one roof,” says Brian Bendig, President of Cavalier Tool.

Why the Okuma MCR‑BV?

When we surveyed the market for a machine that could take our capacity to the next level, one model stood out: the MCR‑BV. Here’s why:

- Massive Work Envelope

With table sizes up to 3000 × 5000 mm and column spacing of 3650 mm, the Okuma MCR‑BV can cradle parts up to 160 inches long and support 35 tonnes of material. That means fewer split setups and more efficiency on large cores, cavities, and fixtures. - Five‑Face & 5‑Axis Mastery

True five‑face indexing plus continuous five‑axis contouring lets us rough, drill, semi‑finish, and finish without re‑fixturing—cutting cycle times by as much as 80% on the right parts. - High‑Torque, High‑Speed Spindle

A 80 kW integral motor/spindle at 6000 rpm delivers up to 1800 N·m of torque for heavy milling, plus the speed needed for fine finishing. - Thermal & Scale Compensation

Okuma’s Thermo‑Friendly Premium system and AbsoScale linear encoders keep the MCR‑BV accurate through temperature swings and long runs—so repeatability is never a question. - Multitasking Attachment Heads

Over 100 head options—straight, right‑angle, universal five‑axis, extension—and an on‑the‑fly Automatic Attachment Changer enable true one‑and‑done machining. - Unattended Productivity

A 180‑pocket tool magazine plus rapid traverses up to 32 m/min let us run lights‑out shifts on large batches.

“Our new MCR‑BV isn’t just big—it’s smart,” Brian explains. “It adapts to each operation, swaps heads and tools automatically, and holds tight tolerances from start to finish. That’s the kind of flexibility our customers need.”

Real‑World Impact for Cavalier’s Customers

Adding the Okuma MCR‑BV to our floor means three major benefits:

Faster Lead Times:

What it means:

Traditional machining often requires multiple setups to rough, drill, and finish a large part—each setup needing manual intervention, repositioning, and rechecking. This not only adds hours of machine downtime but also introduces the risk of error between steps.

How the MCR‑BV helps:

With higher horsepower and multi-axis machining capabilities—including 5-face and 5-axis contouring—the MCR-BV can perform all these operations faster, in a single setup.

That means:

- Fewer machine interruptions

- Less part handling

- Higher removal rates

Customer benefit:

Projects get completed and shipped faster, reducing lead times significantly—especially on large or complex parts. This helps customers keep their own production schedules on track.

Larger, More Complex Parts:

What it means:

Some jobs involve components that are simply too large or intricate for conventional machining centers. In the past, this could mean breaking oversized parts into smaller pieces—which adds cost, delays, and complexity.

How the MCR‑BV helps:

With a work envelope of up to 160 inches in length and the ability to hold 77,000 lbs (35 metric tons), the MCR-BV can handle:

- Oversized blocks

- Tall or wide molds

- Faster, more aggressive milling

Customer benefit:

You get access to tooling for larger, more intricate designs without compromises in lead time or quality—no delays from outsourcing, and no design limitations from smaller machines.

Consistent Precision:

What it means:

Large parts are particularly susceptible to thermal expansion and slight inaccuracies during long machining cycles. Over time, even small errors can lead to out-of-spec results, especially on parts that take days to complete.

How the MCR‑BV helps:

Thanks to Okuma’s Thermo‑Friendly Concept and AbsoScale feedback encoders, the machine actively compensates for:

- Temperature changes in the environment and the machine

- Positioning errors over long axes

It maintains tight tolerances from start to finish—even on multi-day jobs.

Customer benefit:

Every part meets spec, every time. Whether you’re ordering a single mold or a series of matched components, you can count on repeatability and reliability, even at large scale.

“Our customers come to us when they need precision and speed,” Brian says. “With the MCR‑BV, we’re extending that promise to even bigger, more intricate parts—so they can innovate without limits.”

Looking Ahead: Innovation in Action

As we celebrate half a century of service, we’re also charting the next 50 years: faster turnarounds, broader capabilities, and the kind of technical leadership that makes Cavalier Tool the partner of choice for the most demanding tooling projects in the industry.