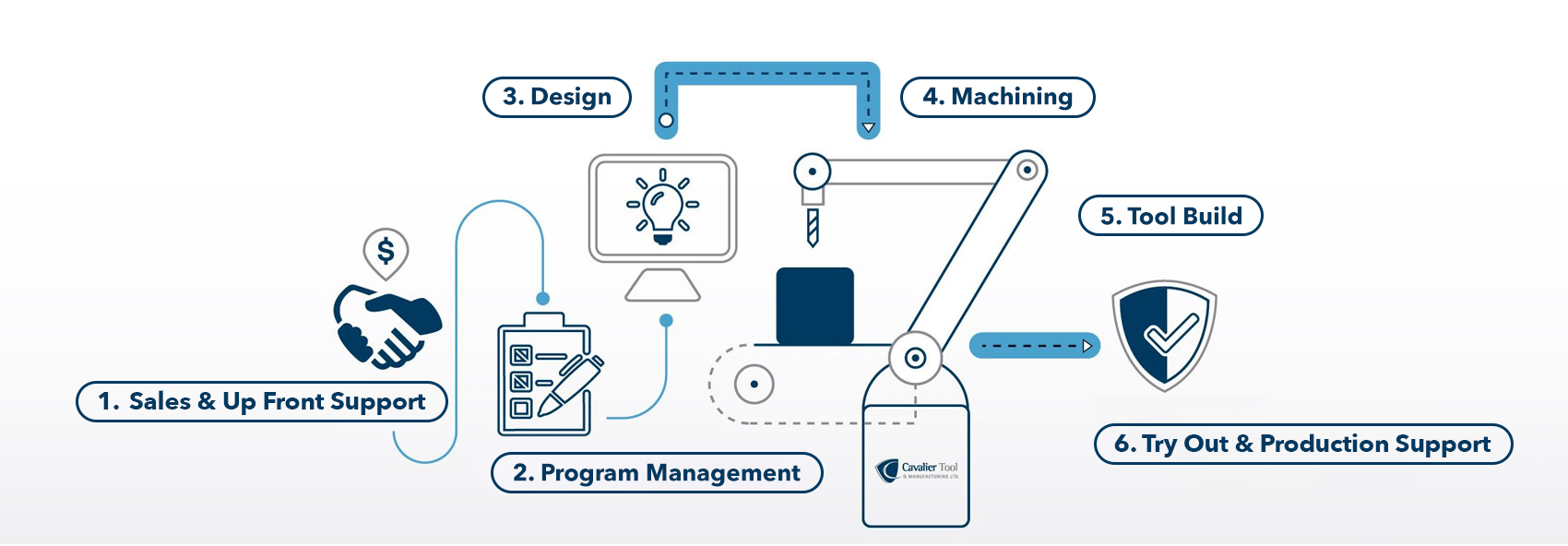

Our Process

Trust In Cavalier

“Our process ensures that we offer advanced technology solution to our customers and that we produce to the highest level of standards, with cost and time efficiency in mind.”

Sales Program Management Design Machining Tool Building Tryout

Sales and Up Front Support:

With our global reach, we develop strategic alliances with both customers and suppliers to continuously improve our support and services. Our highly responsive sales team will guide you to the correct solution for your requirements to ensure your production success. Prior to your order our DFM team will ensure the feasibility of your part to provide moldability, production efficiency, optimal cycle time and a cost-effective tool design. Partner relationships work to make better products.

Program Management:

Responsible for overseeing your tool build from start to finish, our Program Management team offers a full range of support. Our PM’s are proficient in every aspect of tool making. They have the technical skills to oversee design reviews, monitor the build progress, track vendors, and manage your tool build. This is a key component for your project’s success. On time mold builds leading to successful try outs makes your start-up process seamless.

Design:

Our design team is a highly skilled group of leaders utilizing best practices combined with years of experience in developing world class technology that defines Cavalier’s reputation. Our design team starts your project with a hand off from sales that provides the analysis of your parts feasibility. From there our team focuses on designing the best performing tool possible with attention to optimal cycle time, ease of set up and start up, cost effective concepts and a view to durability and long tool life. We are proud of our ability to satisfy customers with the best possible solutions for their production requirements.

Machining:

Cavalier’s machines are custom ordered to insure they are properly integrated into our manufacturing process profile. We actively track utilization for optimal machine run time to support the quickest tool builds. Our unique machine profile ensures we offer the most technologically advanced equipment and cutting process, providing the shortest lead time the tooling industry has to offer.

Tool Build:

Cavalier runs 5 shifts 24/7 meaning your projects are always moving forward. Our capable crews of mold makers are organized into individual teams that look after your project with consistency and dedicated attention to each mold build. This approach ensures a job well done. Our advanced assembly area is well equipped with multiple stations for electrical, hydraulic, and pneumatic services that are run by specific specialists. Our high bay automated parts inventory system holds complete build kits well in advance to provide our mold build teams with the necessary parts on time when needed. Precise mold fitting and assembly takes place with the aid of full design display stations throughout the mold assembly area.

Try Out and Production Support:

During the try out stage, we offer full support while testing your tool, ensuring your quality expectations are met prior to production. On site start up is also part of the Cavalier package as well as post start up support for spare parts and technical help.